Your professional pump manufacturing service provider!

Share

D, DG series multistage pumps

Still decided? Get the samples first,Contact us!

Product classification

Keywords

- Description

-

Overview

Type D pumps are used to transport clear water or liquids with physical and chemical properties similar to clear water, without solid particles, and at temperatures below 80℃. Suitable for mines, factories, and urban water supply and drainage.

Type DG pumps are multi-stage, segmented boiler feed pumps. They are used to transport clear water or other liquids with physical and chemical properties similar to clear water, without solid particles (abrasives). Suitable for medium and low-pressure boiler feed water, and can also be used as general multi-stage centrifugal clear water pumps. The temperature of the liquid being transported is -20~15℃.

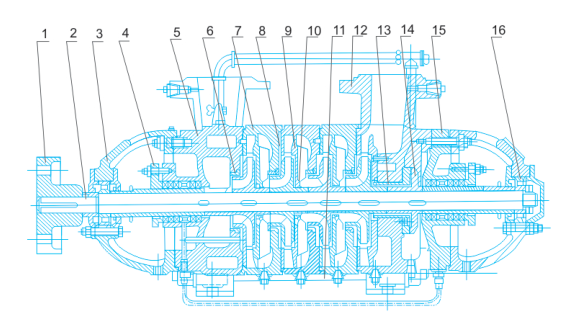

Structural Diagram

1. Pump Coupling

2. Shaft

3. Rolling Bearing Assembly

4. Packing Gland Cover

5. Suction Section

6. Sealing Ring

7. Middle Section

8. Impeller

9. Guide Vane

10. Guide Vane Sleeve

11. Tightening Bolt

12. Discharge Section

13. Balancing Sleeve (Ring)

14. Balancing Disc

15. Stuffing Box

16. BearingPerformance Parameters Table

Model

Speed

Flow Rate

Head (m)

Efficiency

Shaft Power

Motor Power

Required Net Positive Suction Head (NPSH)

D、DG6-25×3

2950

6.3

1.75

75

45

2.86

5.5

2.0

D、DG6-25×4

2950

6.3

1.75

100

45

3.81

7.5

2.0

D、DG6-25×5

2950

6.3

1.75

125

45

4.77

7.5

2.0

D、DG6-25×6

2950

6.3

1.75

150

45

5.72

11

2.0

D、DG6-25×7

2950

6.3

1.75

175

45

6.67

11

2.0

D、DG6-25×8

2950

6.3

1.75

200

45

7.63

15

2.0

D、DG6-25×9

2950

6.3

1.75

225

45

8.52

15

2.0

D、DG6-25×10

2950

6.3

1.75

250

45

9.53

18.5

2.0

D、DG6-25×11

2950

6.3

1.75

275

45

10.5

18.5

2.0

D、DG6-25×12

2950

6.3

1.75

300

45

11.44

18.5

2.0

D、DG12-25×3

2950

12.5

3.47

75

54

4.73

7.5

2.0

D、DG12-25×4

2950

12.5

3.47

100

54

6.30

11

2.0

D、DG12-25×5

2950

12.5

3.47

125

54

7.88

11

2.0

D、DG12-25×6

2950

12.5

3.47

150

54

9.46

15

2.0

D、DG12-25×7

2950

12.5

3.47

175

54

11.0

15

2.0

D、DG12-25×8

2950

12.5

3.47

200

54

12.51

18.5

2.0

D、DG12-25×9

2950

12.5

3.47

225

54

14.18

18.5

2.0

D、DG12-25×10

2950

12.5

3.47

250

54

15.76

22

2.0

D、DG12-25×11

2950

12.5

3.47

275

54

17.34

22

2.0

D、DG12-25×12

2950

12.5

3.47

300

54

18.9

30

2.0

D、DG25-30×3

2950

25

6.94

90

62

9.88

15

2.2

D、DG25-30×4

2950

25

6.94

120

62

13.1

18.5

2.2

D、DG25-30×5

2950

25

6.94

150

62

16.47

22

2.2

D、DG25-30×6

2950

25

6.94

180

62

19.77

30

2.2

D、DG25-30×7

2950

25

6.94

210

62

23.1

30

2.2

D、DG25-30×8

2950

25

6.94

240

62

26.4

37

2.2

D、DG25-30×9

2950

25

6.94

270

62

29.65

37

2.2

D、DG25-30×10

2950

25

6.94

300

62

32.9

45

2.2

D、DG46-30×3

2950

46

12.8

90

70

16.11

22

3.0

D、DG46-30×4

2950

46

12.8

120

70

21.48

30

3.0

D、DG46-30×5

2950

46

12.8

150

70

26.85

37

3.0

D、DG46-30×6

2950

46

12.8

180

70

32.21

37

3.0

D、DG46-30×7

2950

46

12.8

210

70

37.58

45

3.0

D、DG46-30×8

2950

46

12.8

240

70

42.95

55

3.0

D、DG46-30×9

2950

46

12.8

270

70

48.32

55

3.0

D、DG46-30×10

2950

46

12.8

300

70

53.69

75

3.0

D、DG46-50×3

2950

46

12.8

150

63

29.83

37

2.8

D、DG46-50×4

2950

46

12.8

200

63

39.77

45

2.8

Model

Speed

Flow Rate

Head (m)

Required Shaft Power

Motor Power

Required Net Positive Suction Head (NPSH) D、DG46-50×5

2950

46

12.8

250

63

49.71

55

2.8

D、DG46-50×6

2950

46

12.8

300

63

59.65

75

2.8

D、DG46-50×7

2950

46

12.8

350

63

69.6

90

2.8

D、DG46-50×8

2950

46

12.8

400

63

79.54

90

2.8

D、DG46-50×9

2950

46

12.8

450

63

89.48

110

2.8

D、DG46-50×10

2950

46

12.8

500

63

99.42

110

2.8

D、DG46-50×11

2950

46

12.8

550

63

109.36

132

2.8

D、DG46-50×12

2950

46

12.8

600

63

119.3

132

2.8

DG85-45×2

2950

85

23.6

90

72

28.94

37

4.2

DG85-45×3

2950

85

23.6

135

72

43.4

55

4.2

DG85-45×4

2950

85

23.6

180

72

57.87

75

4.2

DG85-45×5

2950

85

23.6

225

72

72.34

90

4.2

DG85-45×6

2950

85

23.6

270

72

86.81

110

4.2

DG85-45×7

2950

85

23.6

315

72

101.3

132

4.2

DG85-45×8

2950

85

23.6

360

72

115.7

132

4.2

DG85-45×9

2950

85

23.6

405

72

130.2

160

4.2

DG155-30×2

2950

155

43

60

77

32.84

55

3.2

DG155-30×3

2950

155

43

60

77

49.26

75

3.2

DG155-30×4

2950

155

43

120

77

65.68

90

3.2

DG155-30×5

2950

155

43

150

77

82.10

110

3.2

DG155-30×6

2950

155

43

180

77

98.52

132

3.2

DG155-30×7

2950

155

43

210

77

114.97

160

3.2

DG155-30×8

2950

155

43

240

77

131.36

180

3.2

DG155-30×9

2950

155

43

270

77

147.78

180

3.2

DG155-30×10

2950

155

43

300

77

164.20

225

3.2

D、DG155-67×3

2950

155

43

201

74

114.7

132

5.0

D、DG155-67×4

2950

155

43

268

74

152.6

185

5.0

D、DG155-67×5

2950

155

43

335

74

191.1

220

5.0

D、DG155-67×6

2950

155

43

402

74

229.3

280

5.0

D、DG155-67×7

2950

155

43

469

74

267.5

350

5.0

D、DG155-67×8

2950

155

43

536

74

305.7

350

5.0

D、DG155-67×9

2950

155

43

603

74

344

440

5.0

DG280-43×2

1480

280

77.8

86

77

85.17

110

4.0

DG280-43×3

1480

280

77.8

129

77

127.7

150

4.0

DG280-43×4

1480

280

77.8

172

77

170.3

230

4.0

DG280-43×5

1480

280

77.8

215

77

212.9

300

4.0

DG280-43×6

1480

280

77.8

258

77

255.5

300

4.0

DG280-43×7

1480

280

77.8

301

77

298.1

350

4.0

DG280-43×8

1480

280

77.8

344

77

304.7

410

4.0

DG280-43×9

1480

280

77.8

387

77

383.2

430

4.0

DG280-65×6

1480

280

77.8

390

73

407.4

500

3.0

DG280-65×7

1480

280

77.8

455

73

475.3

680

3.0

DG280-65×8

1480

280

77.8

520

73

543.2

680

3.0

DG280-65×9

1480

280

77.8

585

73

611.1

850

3.0

DG280-65×10

1480

280

77.8

650

73

579

850

3.0

DG450-60×3

1480

450

125

180

79

229.2

360

4.2

DG450-60×4

1480

450

125

240

79

372.3

500

4.2

DG450-60×5

1480

450

125

300

79

465.4

680

4.2

DG450-60×6

1480

450

125

360

79

558.2

680

4.2

DG450-60×7

1480

450

125

420

79

651.5

850

4.2

DG450-60×8

1480

450

125

480

79

744.6

850

4.2

DG450-60×9

1480

450

125

540

79

837.7

1050

4.2

DG450-60×10

1480

450

125

600

79

930.8

1050

4.2

Quality rest assured

Source manufacturer

Model complete

Support customization

After-sales worry-free

Factory Scene

Workshop Equipment

Application Scenarios

Water treatment and water supply and drainage

Chemical Industry

electric power industry

FAQ

Does the company accept OEM/ODM orders?

The company accepts OEM/ODM orders and can customize product appearance, specifications, packaging, etc. according to customer requirements.

Does the company provide samples?

The company can provide samples according to customer needs, and the customer must bear the sample fee and shipping costs.

How does the company calculate shipping costs?

The freight is calculated based on factors such as the volume, weight, transportation method, and destination of the goods. Feel free to inquire for a detailed freight quote.

How does the company ensure the safety of goods?

The company uses professional packaging materials and reinforcement measures to ensure that goods are safe and intact during transportation.

How does the company arrange for the transportation of goods?

The company has a professional logistics team that can arrange sea, air, or land transportation according to customer needs and provide door-to-door service.

What payment methods does the company accept?

The company accepts various payment methods such as T/T, L/C, D/P, etc., for the convenience of customers to choose.

D, DG series multistage pumps

Still decided? Get the samples first,Contact us!

Product classification

Keywords

INQUIRY IMMEDIATELY

Note: We will contact you within one working day. Please pay attention to your phone or mail.

Related Products

D, DT, and TL series flue gas desulfurization pumps