Your professional pump manufacturing service provider!

Share

G and GH series gravel pumps

Still decided? Get the samples first,Contact us!

Product classification

Keywords

- Description

-

Overview

G and GH type gravel pumps adopt a single pump casing structure with cartridge connection, and the flow passage is wide. The flow components of this sand pump use wear-resistant materials such as hard nickel and high chromium. The discharge port direction of the sand pump can be at any position within 360°, with advantages such as convenient installation and use, good cavitation performance, and corrosion resistance. Among them, the GH type gravel pump is a high-head gravel pump, mainly used for the continuous conveying of strongly abrasive materials with particles too large for general slurry pumps to handle. This type of gravel pump is suitable for dredging with dredgers, dredging rivers, and conveying mining and metallurgical blast slag, etc.

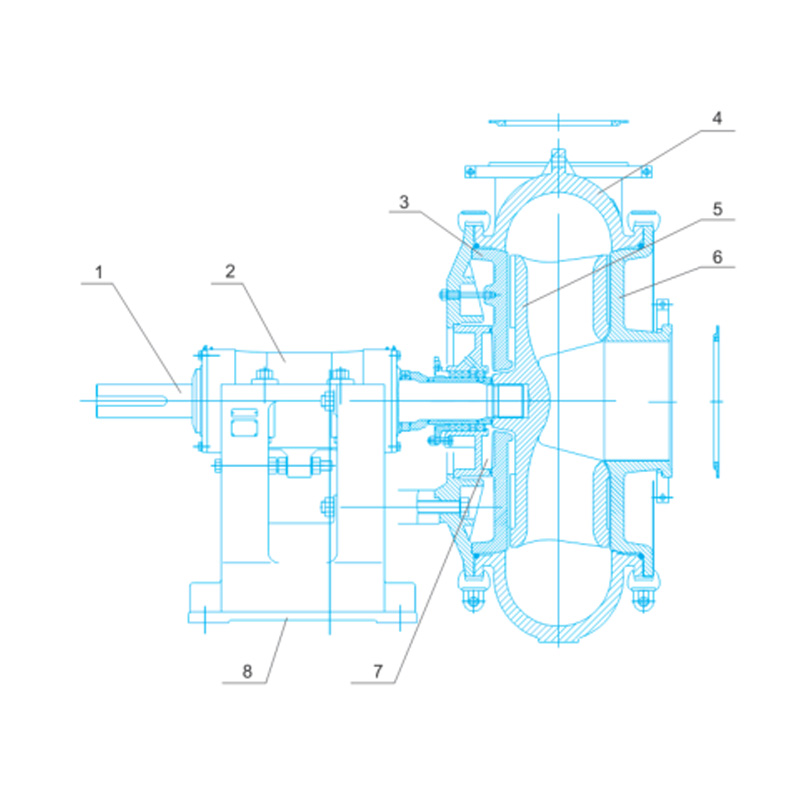

Structural Diagram

1. Shaft

2. Bearing Assembly

3. Rear Guard Plate

4. Pump Body

5. Impeller

6. Pump Cover

7. Stuffing Box

8. Support

Performance Parameters Table

Model Type

Flow (m³/h)

Head H

(m)

Speed n

(r/min)

Efficiency η Eff.

(%)

Shaft Power

(kw)

Transmission Type

Pump External Dimensions Length × Width × Height

(mm)

Pump Weight

(kg)

6/4D-G

187-36

7-51

1400-600

30-58

52-3

CV.CR.DC

1011×705×677

460

8/6E-G

576-133

10-48

1400-800

60-54

88-11

CV.CR.DC

1299×896×873

1120

10/8F-G

930-216

11-44

940-500

65-34

147-22

CR.DC

1597×1121×1089

2285

12/10G-G

1512-360

11-58

850-400

70-50

305-24

CR.DC

2010×1330×1516

4450

14/12G-G

3168-522

9.5-66

700-300

68-60

643-29

CR.DC

2102×1645×648

5400

16/14G-G

3024-900

14-45

500-300

70-50

459-78

CR.DC

2196×1880×1765

8800

8/F-GH

648-126

15-77

1050-500

71-50

177-12

CR.DC

1500×1100×1120

1900

10/8S-GH

1091-324

19.2-26.5

800-500

72-60

205-32.4

CR.DC

1774×1212×1282

3188

12/10G-GH

2232-612

28-77

700-450

73-60

558-89

CR.DC

2211×1734×1500

4638

16/14TU-GH

3420-1008

26-65

450-300

78-65

665-110

CR.DC

2670×1700×2200

12247

Quality rest assured

Source manufacturer

Model complete

Support customization

After-sales worry-free

Factory Scene

Workshop Equipment

Application Scenarios

Water treatment and water supply and drainage

Chemical Industry

electric power industry

FAQ

Does the company accept OEM/ODM orders?

The company accepts OEM/ODM orders and can customize product appearance, specifications, packaging, etc. according to customer requirements.

Does the company provide samples?

The company can provide samples according to customer needs, and the customer must bear the sample fee and shipping costs.

How does the company calculate shipping costs?

The freight is calculated based on factors such as the volume, weight, transportation method, and destination of the goods. Feel free to inquire for a detailed freight quote.

How does the company ensure the safety of goods?

The company uses professional packaging materials and reinforcement measures to ensure that goods are safe and intact during transportation.

How does the company arrange for the transportation of goods?

The company has a professional logistics team that can arrange sea, air, or land transportation according to customer needs and provide door-to-door service.

What payment methods does the company accept?

The company accepts various payment methods such as T/T, L/C, D/P, etc., for the convenience of customers to choose.

G and GH series gravel pumps

Still decided? Get the samples first,Contact us!

Product classification

Keywords

INQUIRY IMMEDIATELY

Note: We will contact you within one working day. Please pay attention to your phone or mail.

Related Products

D, DT, and TL series flue gas desulfurization pumps