Your professional pump manufacturing service provider!

Share

ZJ horizontal slurry pump

Still decided? Get the samples first,Contact us!

Product classification

Keywords

- Description

-

Overview

The ZJ type slurry pump is a horizontal, axial suction, single-stage centrifugal slurry pump. The pump body adopts a double-layer metal structure, with a vertically split volute casing. The discharge port can be rotated to eight different positions at 45° intervals, allowing for full conversion of solid-liquid energy within the pump body and improving the erosion resistance of the flow components. Compared with other slurry pumps, it features high efficiency, energy saving, long service life, good cavitation performance, reasonable structure, reliable operation, and easy maintenance. It is widely used in the power, metallurgy, coal, building materials, and other industries for conveying tailings, concentrate sand, ash, coal slurry, and gravel.

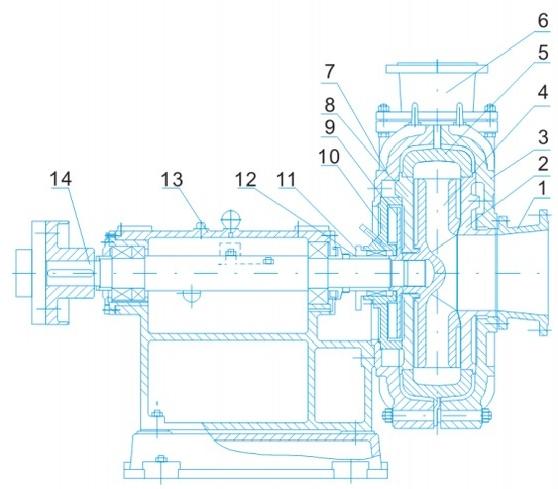

Structural Diagram

1. Inlet Short Pipe

2. Front Wearing Plate

3. Pump Cover

4. Impeller

5. Liner

6. Outlet Short Pipe

7. Pump Casing

8. Rear Wearing Plate

9. Auxiliary Impeller

10. Stuffing Box

11. Stuffing Gland

12. Shaft Sleeve

13. Bearing Assembly

14. Shaft

Performance Parameters Table of ZJ and ZJL Series Slurry Pumps

Model Number

momentum

kw

Water Performance

Discharge

Particle Size

mm

Weight

kg

Flow Rate Q (m³/h)

Head H

Head

m

Speed n (r/min)

%

m

300ZI-I-A110

560

746-1700

33.1-78.0

400-590

71.0

5.0

<49

6300

300ZJ-I-A100

450

619-1826

27.2-67.1

400-590

81.0

4.1

<49

5750

300ZJ-I-A95

400

589-1735

24.6-60.6

400-590

81.0

4.1

<49

5600

300ZJ-I-A90

560

632-1844

33.4-78.0

500-730

82.0

4.8

<45

5000

300ZJ-I-A85

450

596-1742

29.9-69.6

500-730

82.0

4.8

<45

4850

300ZJ-I-A70

630

647-2333

16.7-76.8

500-980

80.4

6.0

<51

4150

300ZJ-I-A65

500

601-2166

14.4-66.2

500-980

80.4

6.0

<51

4000

300ZJ-I-A56

250

403-1568

10.0-48.0

500-980

81.3

5.5

<54

2950

250ZJ-I-A96

560

504-1470

39.9-91.0

500-730

79.0

5.3

<38

5200

250ZJ-I-A90

450

473-1378

35.0-80.0

500-730

79.0

5.3

<38

5150

250ZJ-I-A85

800

384-1504

31.4-129.8

500-980

77.0

5.1

<42

4686

250ZJ-I-A83

710

375-1468

30.0-123.8

500-980

77.0

5.1

<42

4665

250ZJ-I-A80

630

361-1415

27.8-115.0

500-980

77.0

5.0

<42

4630

250ZJ-I-A78

630

352-1380

26.5-109.3

500-980

77.0

5.0

<42

4620

250ZJ-I-A75

500

301-1480

22.3-98.4

500-980

81.6

4.9

<40

3600

250ZJ-I-A73

500

293-1441

21.0-93.2

500-980

81.6

4.9

<40

3590

250ZJ-I-A70

450

288-1380

19.4-85.7

500-980

81.6

4.8

<40

3570

250ZJ-I-A68

355

280-1341

18.3-80.9

500-980

81.6

4.8

<40

3560

250ZJ-I-A65

315

305-1249

15.4-68.5

500-980

79.5

4.7

<40

3550

250ZJ-I-A63

315

295-1211

14.5-64.3

500-980

79.5

4.7

<40

3540

250ZJ-I-A60

250

28-1552

13.1-58.4

500-980

79.5

4.7

<40

3530

200ZJ-I-A75

355

230-900

24.0-103.7

500-980

74.5

4.5

<31

3210

200ZJ-I-A73

355

223-876

22.7-98.2

500-980

74.5

4.5

<31

3190

200ZJ-I-A70

315

240-950

19.9-858

500-980

77.5

4.4

<31

3160

200ZJ-I-A68

280

233-923

18.8-81.0

500-980

77.5

4.4

<31

3140

200ZJ-I-A65

250

240-950

17.2-74.0

500-980

79.3

4.3

<35

2450

200ZJ-I-A63

250

233-921

16.1-69.5

500-980

79.3

4.3

<35

2430

Type

momentum

kw

Water Performance

Water performance

Delivery Granularity

Weight

weight

kg

Flow Q Flow m³h

Head H

Head m

Speed n (r/min)

Love

200ZJ-I-A60

200

223-870

14.6-64.0

500-980

81.4

4.1

<35

2400

200ZJ-I-A58

185

215-841

13.7-59.8

500-980

81.4

4.1

<35

2380

150ZJ-I-A65

200

154-600

18.9-78.5

500-980

75.0

39

<27

2100

150ZJ-I-A65

85

149-582

17.7-73.7

500-980

75.0

3.9

<27

2050

150ZJ-I-A60

160

137-550

15.4-64.5

500-980

77.5

3.8

<27

1800

150ZJ-I-A58

132

132-532

14.4-60.3

500-980

77.5

3.8

<27

1780

150ZJ-I-A55

110

126-504

12.9-54.2

500-980

74.5

38

<27

1760

150ZJ-I-A50

75

117-460

9.9-45.5

500-980

78.0

32

<27

1630

150ZJ-I-A48

75

112-442

9.1-41.9

500-980

78.0

3.2

<27

610

150ZJ-I-A42

132

142-550

12.1-64.0

700-1480

75.0

4.5

<35

1550

100ZJ-I-A50

160

86-360

20.2-101.6

700-1480

71.3

4.1

<19

1440

100ZJ-I-A46

132

79-331

17.1-86.0

700-1480

71.3

4.1

<19

1310

100ZJ-I-A42

90

68-275

14.6-71.0

700-1480

71.0

3.9

<20

1078

100ZJ-I-A39

75

63-255

12.6-61.2

700-1480

71.0

3.9

<20

1060

100ZJ-I-A36

45

61-245

9.1-48.6

700-1480

76.0

3.6

<20

890

100ZJ-I-A33

37

57-255

7.7-40.8

700-1480

76.0

3.6

<20

870

80ZJ-I-A42

75

61-260

13.3-70.6

700-1480

67.8

3.5

<13

970

80ZJ-I-A39

75

56-241

11.4-60.9

700-1480

67.8

3.5

<13

945

80ZJ-I-A36

45

45-190

10.0-51.5

700-1480

70.8

3.0

<13

885

80ZJ-I-A33

37

41-174

8.4-43.0

700-1480

70.8

3.0

<13

860

65ZJ-I-A30

15

23-80

7.4-35.8

700-1480

63.5

3.0

<11

820

65ZJ-I-A27

11

20-72

6.0-29.0

700-1480

63.5

3.0

<11

795

40ZJ-I-A17

4

5-20

7.0-33.6

1390-2890

53.0

2.5

<10

430

150ZJL-35

37

119-364

4.4-17.8

590-980

68.1

900

100ZJL-32

45

130-385

10.7-29.0

970-1480

68.0

850

80ZJL-36

45

69-201

14.0-45.5

970-1480

58.2

660

50ZJL-20

4

12-39

2.6-10.2

940-1440

41.2

250

Quality rest assured

Source manufacturer

Model complete

Support customization

After-sales worry-free

Factory Scene

Workshop Equipment

Application Scenarios

Water treatment and water supply and drainage

Chemical Industry

electric power industry

FAQ

Does the company accept OEM/ODM orders?

The company accepts OEM/ODM orders and can customize product appearance, specifications, packaging, etc. according to customer requirements.

Does the company provide samples?

The company can provide samples according to customer needs, and the customer must bear the sample fee and shipping costs.

How does the company calculate shipping costs?

The freight is calculated based on factors such as the volume, weight, transportation method, and destination of the goods. Feel free to inquire for a detailed freight quote.

How does the company ensure the safety of goods?

The company uses professional packaging materials and reinforcement measures to ensure that goods are safe and intact during transportation.

How does the company arrange for the transportation of goods?

The company has a professional logistics team that can arrange sea, air, or land transportation according to customer needs and provide door-to-door service.

What payment methods does the company accept?

The company accepts various payment methods such as T/T, L/C, D/P, etc., for the convenience of customers to choose.

ZJ horizontal slurry pump

Still decided? Get the samples first,Contact us!

Product classification

Keywords

INQUIRY IMMEDIATELY

Note: We will contact you within one working day. Please pay attention to your phone or mail.

Related Products

D, DT, and TL series flue gas desulfurization pumps