Your professional pump manufacturing service provider!

Share

D, DT, and TL series flue gas desulfurization pumps

Still decided? Get the samples first,Contact us!

Product classification

Keywords

- Description

-

Overview

The DT and TL series flue gas desulfurization pumps are developed and manufactured by our company for desulfurization purification devices of coal-fired units in thermal power plants. They are mainly used in wet desulfurization systems to transport limestone and gypsum slurry.

Based on existing technologies and drawing on the characteristics of similar products at home and abroad, the product boasts high efficiency, safe and reliable operation, convenient maintenance, and a long service life.

This series of pumps can also be used to transport liquids containing corrosive substances and tiny solid particles in metallurgical, mining, and coal industries; they can also be used for municipal sewage treatment and river dredging.

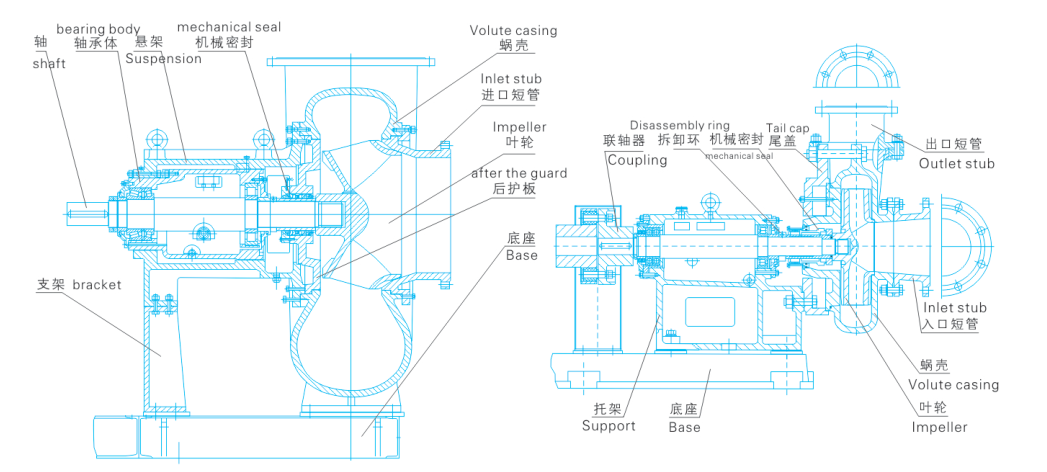

Structural Diagram

Performance Parameter Table

Model

Speed n

Clear Water Performance

Matching Motor

Flow Rate Q

Head H

Shaft Power kw

Maximum Efficiency η%

Net Positive Suction Head

p m

Model

Power/Voltage

kw/v

800DT-A90 800D-A90

592

6200

28.7

553.2

87.6

2.7

Y560-10

710/6000

8800

26.1

700.4

89.3

3.5

Y560-10

900/6000

9700

23.5

715.2

86.8

3.9

Y560-10

900/6000

492

5170

20.0

321.5

87.6

2.0

Y500-12

400/6000

7338

18.1

405.0

89.3

2.5

Y560-12

500/6000

8089

16.3

413.7

86.8

2.9

Y630-12

560/6000

700DT-A84 700D-A84

591

4250

24.5

326.3

86.9

2.8

Y500-10

500/6000

6300

22.3

430.9

88.8

3.5

Y500-10

560/6000

7360

20.1

467.4

86.2

4.0

Y500-10

630/6000

493

3545

17.0

188.9

86.9

2.0

Y450-12

250/6000

5255

15.5

250.0

88.8

2.6

Y500-12

315/6000

6140

14.0

271.6

86.2

3.0

Y500-12

355/6000

600DT-A82 600D-A82

595

3300

27.8

343.2

72.8

3.0

YKK5601-10

500/6000

4700

24.7

358.0

88.3

3.7

YKK5601-10

500/6000

5300

21.7

362.9

86.3

4.0

YKK5601-10

500/6000

5600

20.4

368.2

84.5

4.0

YKK5601-10

500/6000

490

2718

18.9

192.2

72.8

2.2

YKK5003-12

280/6000

3871

16.8

200.6

88.3

2.8

YKK5003-12

280/6000

4365

14.7

202.5

86.3

3.0

YKK5003-12

280/6000

4612

13.8

205.1

84.5

3.0

YKK5003-12

280/6000

500DT-A85 500D-A85

591

2040

26.8

204.5

72.8

4.1

Y450-10

250/6000

3400

24.4

266.7

84.7

Y450-10

355/6000

4080

22.0

305.2

80.1

Y500-10

400/6000

493

1702

18.6

118.4

72.8

3.1

Y450-12

220/6000

2836

17.0

155.0

84.7

Y450-12

220/6000

3403

15.3

177.0

80.1

Y450-12

220/6000

350DT-A78 350D-A78

740

1332

51.1

289.6

64.0

6.5

Y450-8

355/6000

2431

44.5

377.7

78.0

Y500-8

500/6000

2865

39.6

408.7

75.6

Y500-8

500/6000

590

1062

32.5

146.9

64.0

3.5

Y450-10

185/6000

1938

28.3

191.5

78.0

Y450-10

250/6000

2284

25.2

2073

85.6

Y450-10

280/6000

300DT-A60 300D-A60

989

1170

53.1

235.6

71.8

8.4

Y400-6

315/6000

1779

47.1

281.4

81.1

Y400-6

355/6000

2403

36.1

313.3

75.4

Y400-6

400/6000

742

878

29.9

99.6

71.8

4.3

Y355M1-8

132/380

1335

26.5

118.8

81.1

Y355M2-8

160/380

1803

20.3

132.3

75.4

Y355M2-8

160/380

200DT-B45 200D-B45

990

279

31.0

37.4

62.9

3.3

Y280M-6

55/380

557

26.1

49.0

80.8

Y315S-6

75/380

645

23.3

52.6

77.8

Y315S-6

75/380

730

206

16.9

15.1

62.9

2.0

Y225M-8

22/380

410

14.2

19.9

80.8

Y250M-8

30/380

475

12.7

21.1

77.8

Y250M-8

30/380

150DT-B55 150D-B55

990

280

53.7

64.8

63.2

3.7

Y315M-6

90/380

517

48.0

88.3

76.5

Y315L1-6

110/380

630

45.9

100.8

78.1

Y315L2-6

132/380

740

209

30.0

27.0

63.2

2.3

Y280S-8

37/380

387

26.8

36.9

76.5

Y315S-8

55/380

471

25.7

42.2

78.1

Y315S-8

55/380

150DT-A50 150D-A50

980

123

44.6

27.6

54.1

3.5

Y250M-6

37/380

221

40.1

36.9

65.4

279

37.2

43.4

65.2

Y280M-6

55/380

Y280M-6

55/380

730

92

24.7

11.4

54.1

2.1

Y225S-8

18.5/380

165

22.3

15.3

65.4

Y225M-8

22/380

208

20.6

17.9

65.2

Y250M-8

30/380

Model

Speed n

r/min

Clear Water Performance

Matching Motor

Flow Rate Q m³/h

Head H

m

Shaft Power

kw

Maximum Efficiency

η%

Net Positive Suction Head m

Model

Power/Voltage kw/v

150DT-A40 150D-A40

1490

260

61.2

68.8

63.0

6.5

Y280M-4

90/380

440

53.8

88.2

73.1

Y315S-4

110/380

503

50.7

95.4

72.8

Y315M-4

132/380

980

171

26.5

19.6

63.0

2.6

Y225M-6

30/380

289

23.3

25.1

73.1

Y250M-6

37/380

331

21.9

27.1

72.8

Y250M-6

37/380

100DT-A60 100D-A60

1490

152

147.0

133.4

45.6

4.9

Y315M2-4

160/380

256

138.5

170.9

56.5

Y315L2-4

200/380

305

131.7

188.9

57.9

Y355M1-4

220/380

990

101

64.9

39.1

45.6

2.4

Y280S-6

45/380

170

61.2

50.1

56.5

Y315S-6

75/380

203

58.1

55.5

57.9

Y315S-6

75/380

100DT-A45B 100D-A45B

1480

88

76.4

43.6

42.0

6.0

Y250M-4

55/380

166

65.2

56.9

51.8

Y280S-4

75/380

219

54.3

66.5

48.7

Y280M-4

90/380

970

57

32.8

12.1

42.0

2.4

Y200L1-6

18.5/380

109

28.0

16.0

51.8

Y200L2-6

22/380

144

23.3

18.8

48.7

Y225M-6

30/380

100DT-B40 100D-B40

1480

129

61.0

38.7

56.9

3.5

Y250M-4

55/380

219

56.1

48.7

68.7

Y280S-4

75/380

268

53.6

55.6

70.4

Y280S-4

75/380

970

85

26.2

10.7

56.9

1.7

Y180L-6

15/380

144

24.1

13.8

68.7

Y200L2-6

22/380

176

23.0

23.3

70.4

Y200L2-6

22/380

80DT-B36

80D-B36

1480

86

47.1

28.5

47.7

3.2

Y200L-4

30/380

151

42.0

29.3

60.7

Y225S-4

37/380

167

39.9

6.5

62.0

Y225S-4

37/380

970

56

20.2

8.0

47.4

1.5

Y160L-6

11/380

99

18.0

8.2

60.7

Y180L-6

15/380

109

17.1

15.7

62.0

Y180L-6

15/380

65DT-A40 65D-A40

1480

71

63.2

26.2

46.7

4.5

Y225S-4

37/380

141

57.5

35.6

62.1

Y225M-4

45/380

159

54.6

38.1

62.1

Y250M-4

55/380

970

47

27.1

7.4

46.7

2.1

Y160L-6

11/380

92

24.7

10.1

62.1

Y180L-6

15/380

104

23.5

10.7

62.1

Y180L-6

15/380

65DT-A30 65D-A30

1470

44

35.6

9.1

46.7

4.6

Y160L-4

15/380

79

32.6

12.8

54.6

Y10M-4

8.5/380

99

30.7

15.4

53.8

Y180L-4

22/380

960

29

15.2

2.6

46.7

2.2

Y132M2-6

5.5/380

51

13.9

3.5

54.6

Y132M2-6

5.5/380

64

13.1

4.2

53.8

Y160M-6

7.5/380

50DT-D40 50D-D40

1470

33

51.7

13.1

35.4

2.5

Y180M-4

18.5/380

68

43.4

17.8

45.1

Y200L-4

30/380

76

40.8

18.9

44.7

Y200L-4

30/380

970

22

22.5

3.8

35.4

1.2

Y132M2-6

5.5/380

45

18.9

5.1

42.1

Y160M-6

7.5/380

50

17.7

5.4

44.7

Y160L-6

11/380

40DT-B20 40D-B20

2930

16.6

57.5

6.4

40.9

3.5

Y160M1-2

11/380

33.3

49.9

8.5

53.0

Y160M2-2

15/380

37.1

47.1

9.2

52.0

Y160M2-2

15/380

1430

8.1

13.7

0.7

40.9

0.9

Y90L-4

1.5/380

16.3

11.9

1.0

53.0

Y100L1-4

2.2/380

18.1

11.2

1.1

52.0

Y100L1-4

2.2/380

25DT-A25

25D-A25

1440

9.6

21.6

1.7

33.2

7.1

Y100L2-4

3/380

17.8

16.6

2.1

38.0

Y112M-4

4/380

19.9

13.9

2.2

33.8

Y112M-4

4/380

910

6.0

8.6

0.4

33.2

3.3

Y90S-6

0.75/380

11.2

6.6

0.5

38.0

Y90K-6

1.1/380

12.5

5.5

0.6

33.8

Y90L-6

1.1/380

Quality rest assured

Source manufacturer

Model complete

Support customization

After-sales worry-free

Factory Scene

Workshop Equipment

Application Scenarios

Water treatment and water supply and drainage

Chemical Industry

electric power industry

FAQ

Does the company accept OEM/ODM orders?

The company accepts OEM/ODM orders and can customize product appearance, specifications, packaging, etc. according to customer requirements.

Does the company provide samples?

The company can provide samples according to customer needs, and the customer must bear the sample fee and shipping costs.

How does the company calculate shipping costs?

The freight is calculated based on factors such as the volume, weight, transportation method, and destination of the goods. Feel free to inquire for a detailed freight quote.

How does the company ensure the safety of goods?

The company uses professional packaging materials and reinforcement measures to ensure that goods are safe and intact during transportation.

How does the company arrange for the transportation of goods?

The company has a professional logistics team that can arrange sea, air, or land transportation according to customer needs and provide door-to-door service.

What payment methods does the company accept?

The company accepts various payment methods such as T/T, L/C, D/P, etc., for the convenience of customers to choose.

D, DT, and TL series flue gas desulfurization pumps

Still decided? Get the samples first,Contact us!

Product classification

Keywords

INQUIRY IMMEDIATELY

Note: We will contact you within one working day. Please pay attention to your phone or mail.

Related Products

D, DT, and TL series flue gas desulfurization pumps