Your professional pump manufacturing service provider!

Contact Us

E-mail:

liquan3426959@gmail.com

WhatsApp:

+86-13663114444

Address:

No.1, Row 3, Street 3, District 6, Lujing Village, Shifo Town, Anguo City, Baoding City

Product

YW submersible sewage pump series

YW submersible sewage pumps are suitable for various industries, including chemical, petrochemical, pharmaceutical, mining, papermaking, cement plants, steel plants, power plants, coal processing, and municipal wastewater treatment plants, as well as municipal engineering construction sites. They can transport sewage and waste containing particles, and can also be used to pump clean water and corrosive media.

Features include high efficiency, energy saving, long service life, good cavitation performance, reasonable structure, reliable operation, and easy maintenance.

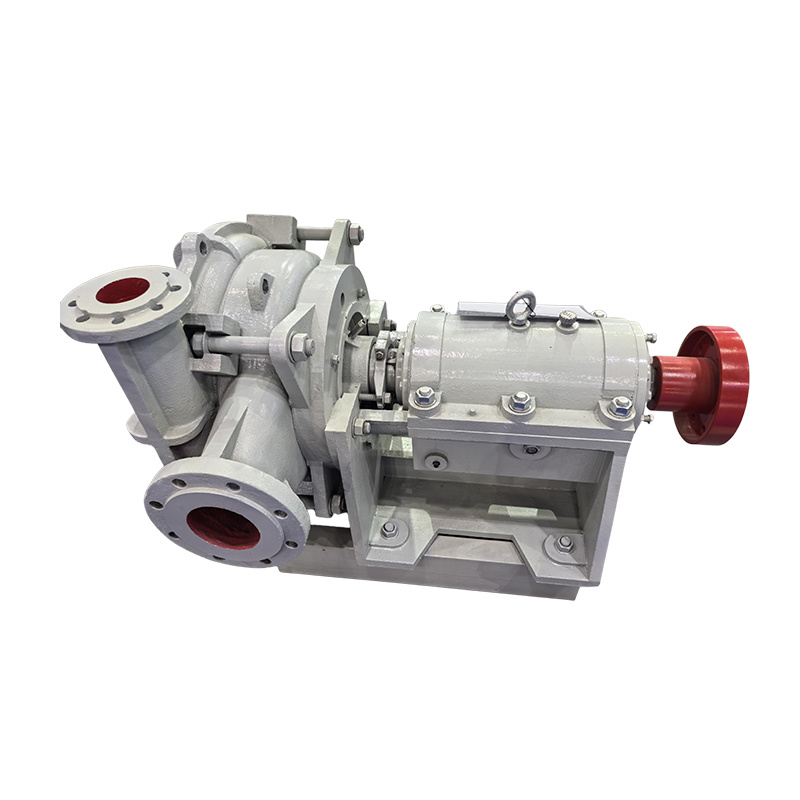

M, AH, and HH type pumps are cantilever, horizontal, centrifugal slurry pumps. They are suitable for transporting highly corrosive, high-concentration slurries in metallurgical, mining, coal, power, and building materials industries. These pumps can also be used in multi-stage series.

YZ submersible slurry pump, WZ horizontal slurry pump

The YZ submersible slurry pump is a vertical, single-stage, single-suction, cantilever centrifugal pump structure. The impeller is a semi-open impeller, and stirring blades are provided at the extension of the impeller suction side.

SYA type plate filter press feed pump

The SYA type filter press feed pump is a filter press-specific feed pump product designed and developed using advanced fluid theory and combined with the feed conditions of various filter press applications.

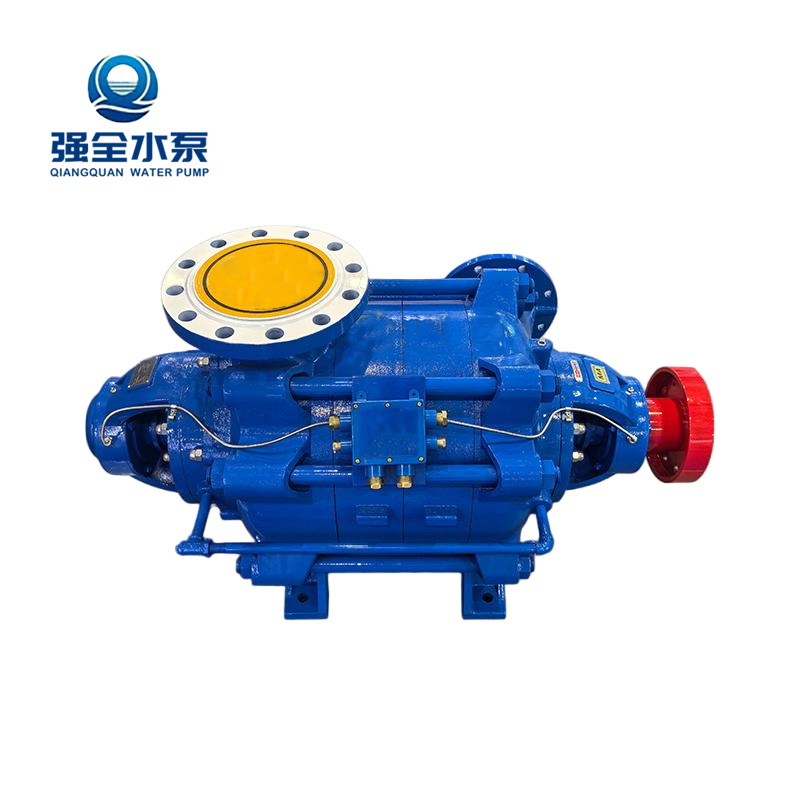

D-type pumps are suitable for conveying clear water or liquids with physical and chemical properties similar to clear water, without solid particles, and at temperatures below 80℃. They are suitable for mines, factories, and urban water supply and drainage.

SP, SPR series submersible slurry pumps

SP and SPR pumps are vertical, submersible, centrifugal slurry pumps used for transporting abrasive, coarse-grained, high-concentration slurries. They require no shaft seals or seal water and can operate normally even under conditions of insufficient suction. SP pumps have wear-resistant metal pump bodies, and impellers made of wear-resistant metal or rubber/polyurethane. The submersible components of the SPR pump are rubber-lined, suitable for transporting corrosive slurries.